- Tel: +86-592-7162735

- Mobile: Abby(Sales03):+86-13779960061;Audrey:+86-13799736862

- E-mail: sales03@xmekay.com

- E-mail: audrey@xmekay.com

- Add: Fuming Road 190, Tong`an District ,Xiamen City ,China

- Skype: xmekay01

- QQ: Whatsapp: audreylian6862

- Province/State: Xiamen

How to DIY carbon fiber frame?

2016-06-14

Background: Want a favorite road car. But hundreds of thousands of thousands of prices, and so let me tear Cock wire mesh.

Carbon fiber coating process, has a low weight, high strength, relatively simple production environment. The most important is without sophisticated equipment, hands and enough patience OK. It is the best choice for this type of DIY.So I worked hard for many years right hand finally came in handy.

Started before.

Have to go on the website once FITTING, this is a necessary process. It can be drawn in line with the effective stretching length of your body, the head tube length, the length of the riser. By querying the size of the vehicle. I can see that a suitable geometry rack for head angle of 73 degrees. Riser angle is 74 degrees. Effective extension length of 66 (minus the radius of the seat tube and head tube radius and stem length 11CM) 66-11-1.5-1.8- thickness error, I need the tube length 52CM. (Note that the horizontal tube and we need to do on the tube 2 is a bit different)The length of the head pipe. One way is to direct the amount of riding you around you feel right car head pipe. Another method is based on the G or M frame size table in line with the head tube length to your height shelf. Unless you can find one you rode very appropriate frame as a template. Otherwise, please FITTING data subject, whichever is the basis to FITTING accurate data of your own body measurements.

Necessary accessories: 1, the seat tube adjustable sets lengthened. 30.8 27.2 turn.

Head tube and headset can install an external headset. Because I was doing road vehicle use 34MM bowl group, so long as it is 34MM of aluminum or carbon nanotubes can be.

Five. This has several specifications, though they are 68MM, but one is ordinary five, on an ordinary VP ball axis. There BB30 conversion units, one for ordinary British

regulatory tooth plate. This depends on what your late suites available. I use the figure of the British regulations converted sets do axis. Disc hi Mano one tooth on. . Compact disc. The way to work because there is a long uphill

Over the clamp. Cylindrical clip directly Vehicle, half-pass, then re-direct AB fill soil Nianshang Qu cladding carbon cloth painted point resin is fixed. Then use the saw blade to saw out the slot on the OK

Front derailleur clamp ring conversion. (Cylindrical seat tube clamp directly) on the tag through the front derailleur

Also from a universal treasure. . . Pre-open hole. Hand turn at an angle change. Keel a fork, AB fill soil one. What a perfect harmony of things ah. . . . . . After my needle in a haystack search. . . could not find it. . Results later bought the seat tube clip was found out something. . . . This is how you have to pit father ah. .

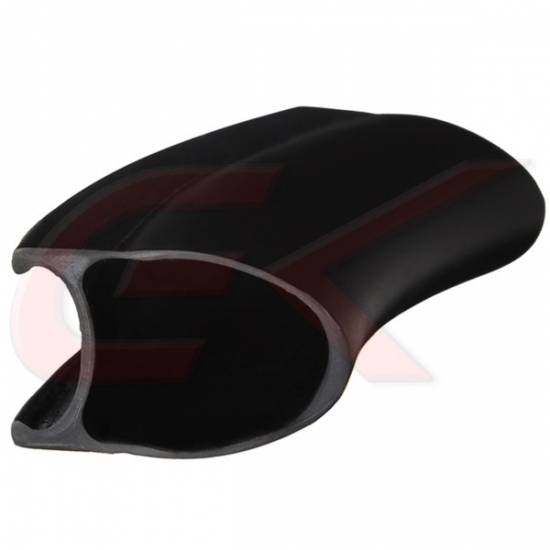

Carbon cloth. Any carbon car the whole car is not using the same cloth. Although we are doing Cock wire carbon, but the emphasis is to pay attention to. I used three types of carbon fiber cloth.

T700 12K unidirectional fabric used in the lowest layers of 10CM wide. About 4 meters can be all car pack 1 layer. 10 yuan per meter

Kevlar blended fabrics make up for toughness force part 1 square meter (head tube and down tube junction. Five-part. Seat tube to the pipe connections after the fork up and down)

T700 3K cloth used for the outermost layer 2 simply for aesthetics 1 square meter

The final analysis, or resources, the Internet basically the only way, if the conditions can be used interchangeably T700 T800, if they can get a better high modulus. . . . .

Before the Internet has a foreigner to do carbon fiber shelf. . . Foam core made use of. . . . . I was also ready to follow suit. . . But when the bubble hand, alone, I do find a saw blade. . . He wanted to do that level of foam models, I guess my next life too. . . then. . . I had an idea. . . Directly molded carbon fiber tubes do keel. . .34X36 (1 meter) as the down tube and head tube, 26X30 (1 meter) as the riser pipe and the (then turn 27.2 30.8 tube adjustable sets). 25.4 on the seat tube. Of course, the lower portion of the seat tube package have one layer or two layers of carbon fiber thickening to comply caliber. I would have a tube with 30X27, and would like the 27.2 seat tube, the result after several reinforcement, which are 2 mm error not fit into. . . . . 8X6 (rear two meters as the fork and rear lower fork), why this caliber, because the fork piece is almost open holes 8 mm, brake caliper on that hole diameter is 8MM. It is not too thin, because it is only from a functional keel, after reinforcing it rough. . .

Material substantially on these. by those in the process may need to be aware of the problem. .

1. curing requires the ambient temperature above 25 degrees, this good meet, probably the higher the temperature, the faster the dry.

2. After applying glue 3 ~ 5H (that is has begun to surface dry resin) must not be re-warmed! Otherwise it will destroy the normal resin solidification, so no matter how long it will not be cured!

3. The resin with a good try after 15 minutes after use, do not tune a lot of gum, so as not to affect the back of the resin begins to cure the coating. The proportion of resin and hardener I used a 2: 1 volume ratio of 1.8: 1 I did not engage in things like electronic scales, go to a nearby clinic to find a few vials loaded penicillin. 1 bottle 2 bottle resin with a curing agent, a practical point of view, the error is not great. Effect no effect. . . . .

4. The shelf is a must, whatever you want any way, Ye wood, aluminum or, anyway, when you got to have a mosaic of fixed shelves. Order is to fight on the front fork and rear triangle and rear lower fork

5. The pre-coated reinforcement. Try to use piece of cloth to be coated. After the carbon fiber tube length to take a good 3-5 times and then reinforced. Remember to leave a few centimeters. . For example, your horizontal tube 53 need, you sawn 57 .. . Since early after reinforcing it several times, leaving both ends certainly a lot of cloth. . Polished too much trouble. . After the completion of the pre-reinforcement, directly before and saw two centimeters. The rest is a strength and a good sell are good on the tube. Ha ha ha

6. The coated carbon fiber directionality. Never in the same direction. . . You can cross. vertical. cross. Wound. Used interchangeably.

7. Try to use a known angle frame. After all, we are hand-DIY, do not have the ability to force analysis, imagination can be, but to science. . . . The weight of the frame should not be too demanding, after all, we are handmade carbon intensity is the first, and probably the final product is about 1500 grams, excluding fork. After all, it costs about 1,000 yuan, demanding what we do. . . PS I was doing when I saw dad once said to me once, saying how could stick welding solid ratio. . . Finally, I strongly several times more. . Results overweight. . . 1700 g

8. Carbon fiber sheet can choose 1.5X0.6 specifications. Because in general a single pipe length does not exceed 60CM, you can maximize the use of materials. If not casually 1X1 is also OK. . Cutting by double-sided adhesive seal on both sides. . . otherwise. Carbon cloth will be scattered. . . . .

9. The principle is this principle, our actual operating order is to polish the lower surface and the backing plastic, etc. 1-2 hours, the glue dry a little time to start wrapping cloth. Wrap after brush the mixture of resin and hardener. Then wound PVC electrical tape to help shape. If you need to discharge excess glue to tie hole in the electrical tape, not exclusively, do not tie. Do not wear a tie, and the difference is. . For example, pre-reinforced tubing. If you do not have a strong tie three times, five times stronger on the bar. . Strong will be thicker or five times more. . .

10. The method of fixing carbon fiber frame five-way, etc.

11.AB fill soil, the good stuff, the adhesive used for assembling the frame, and place late uneven patches. The disadvantage is that .. heavy ..

The double-sided adhesive tape is widely used and electrical supplies. When double-sided tape for cutting carbon cloth help shape and when the package given location. PVC electrical tape after the resin used to help shape the brush, is not the best place with a resin glue directly torn on OK after a good cure.

Source:tieba

Welcome to visit our website http://www.carbonwheelfactory.com/ to learn more information about carbon bike wheels,carbon road bike rims,carbon mountain bike wheelset,carbon fat bike rim and carbon fiber bike wheel.

Previous :MIT Carbon fiber bike reviews